Circular Supply Chains: Quantifying their Resilience in the Face of Disruptions

|

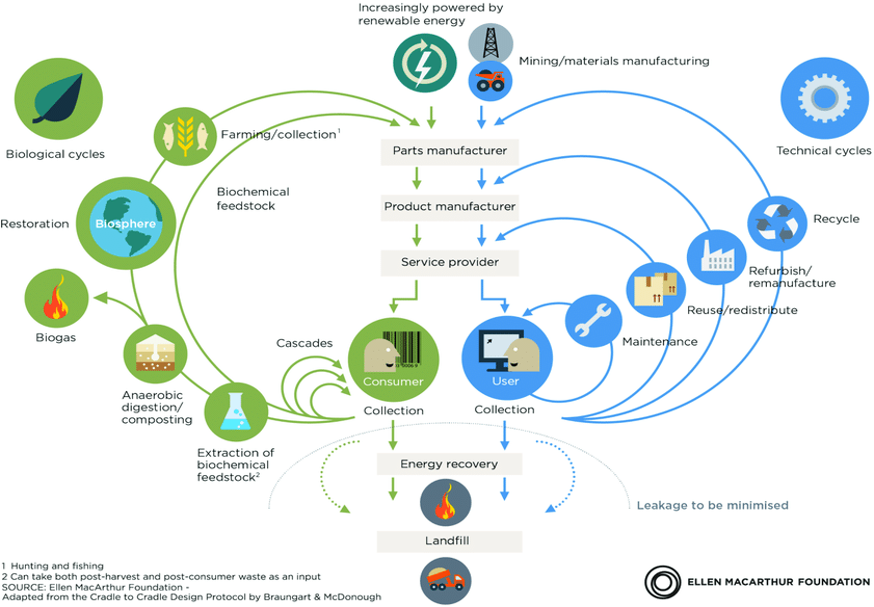

As illustrated by the 2030 Agenda for Sustainable Development and the Paris Agreement on Climate Change, the EU is committed to consistently progressing towards sustainable industrial practices. Circular economy (CE) is a sustainable economic paradigm that aims at prolonging the resource value as long as feasible, by promoting the continuous reuse of resources and products, recapturing value from by-products and end-of-life resources, and minimising resource leakage out of the systems. Circular Supply Chain (CSC) is a self- regenerative ecosystem adopting the principles of Circular Economy to extract new value from end-of-life resources, extend material life, and increase resource efficiency toward zero-waste operating conditions. CSCs extend the boundaries of closed loop supply chains (SCs) by involving multiple stakeholders, with both firms belonging to the linear supply chain stages and organizations from the external industrial networks, carrying out the circular activities. Several examples have been provided by previous works, where recycled polyethylene terephthalate (PET) bottles and textile materials may be used for construction or waste cooking oil from a food supply chain utilized to produce bio-fuels. Despite the highly-anticipated benefits of CSCs, the current literature on the topic is rather limited and invites further studies.

In this project, we propose a general framework for analyzing the resiliency of CSCs. Without a doubt, CSC networks should be resilient to better perform in the advent of frequent and unpredictable disruptions. Similar to linear supply chains, the stability of CSC networks can be jeopardized by adverse events that can occur at different levels, for instance, within each facility (e.g. warehouse), within single firms (intrafirm), between different firms (inter-firm), and at the global level. Machine malfunctioning, natural disasters (earthquakes, volcano eruptions), terrorist attacks, political turbulence, economic crises, and diseases (Covid-19, SARS) are just a few examples

Acknowledging the ripple effect of disturbances, we develop a framework that models the dynamics and equilibrium state of a supply chain and offer an exact algorithm for computing the new equilibrium state of CSC after a disruption. Using this methodology, we are able to accurately analyze the resilience of CSC in the face of different types of disturbances occurring when handling, storing and transporting materials. Moreover, we provide a measure that quantifies the benefits of CSC when compared to linear supply chains. Using this framework, we are not only able to assess the resilience of existing CSCs but also determine which nodes (e.g. warehouse, firm) and arcs (e.g. connection, flow, operation) are the most important contributors to the resilience of the network. Finally, the metric can also be readily used to assess future investments/expansions on material handling systems of the existing supply chain network.